Audi has made significant advancements in the development of their synthetic e-fuels. Most recently, the e-fuels completed a test cycle in a pressure chamber and a see-through glass engine, where engineers found the e-fuels often perform better than their conventional counterparts.

Looking to investigate the synthetic fuels combustion characteristics, Audi engineers simulated conditions inside an engine using a pressure chamber, which had been pressurized up to 15 bar and heated to 350 degrees. A special camera recorded how the e-fuels behave during the injection process, as only a clean air/fuel mixture will assure ideal combustion.

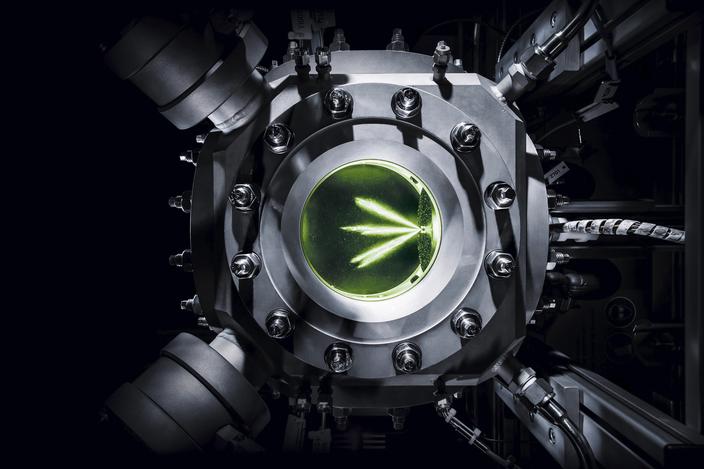

The glass engine is another station used to test the fuels. The glass engine reveals the processes which are normally hidden behind metal cylinder walls. A small glass window allows the engineers to observe the fuels behaviour in the combustion chamber. Audi says during each of the 3,000 rotations per minute in the research engine, a small amount of fuel shoots into the cylinder, is compressed and ignited and the exhaust gas is then expelled, just like a normal engine.

Thanks to these two observation techniques, Audi engineers were able to conclude that unlike fossil fuels, the composition of which varies depending on their place of origin, Audi e-fuels are pure and consistent. Fewer emissions are generated when they are burned and they do not contain olefin or aromatic hydrocarbons, the latter of which is one of the most widespread organic pollutants.

Audi engineers will now look at ways to optimize the production processes of their e-ethanol and e-diesel synthetic fuels. At Audi’s research facility in New Mexico, scientists use microorganisms, water, sunlight and oxygen to produce the high-purity fuels. Once the production process has been perfected, Audi says the fuels will be ready for the market.

No Comments yet