Back in February, Ford started production of the 2015 Ford Edge, the very first global vehicle to roll off the lines at Oakville, Assembly plant in Ontario, Canada. To ensure the world debut of the new midsize crossover up to snuff, Ford has revamped the plant’s processes and production techniques to ensure that the first-ever global Edge is up to quality standards and ready for worldwide markets.

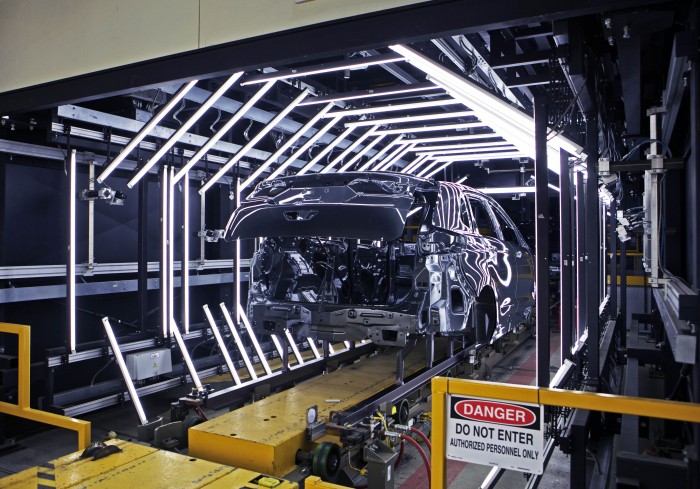

The plant, which received a $700 million injection from Ford last year, now features a three-dimensional dirt detector that uses 16 HD cameras to scan Ford Edges in production and locate paint imperfections. The cameras notice even the tiniest flaws with considerable accuracy, and the results are instantly shown on a series of monitors located on the outside of the scanning booth. Derek Power, manufacturing engineering technical analyst and team manager at Oakville Assembly, says its one of the world’s most innovative pieces of 3D dirt detection equipment.

But the HD dirt detector is just one example of the next-generation technologies Ford is using to produce the new Edge. Check out what else Oakville Assembly has up its sleeve in the video.

Comments